Nanocrystalline bulk materials: Production by SPD and Selected Properties

Project coordinator: Univ.-Prof. Dr. R. Pippan (Austrian Academy of Science, Leoben)

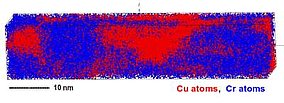

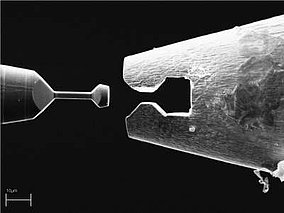

At the ESI High Pressure Torsion (HPT), Equal Channel Angular Pressing (ECAP), and Cyclic Channel Die Compression (CCDC), a special type of multiforging has been installed and successfully ap-plied to many different materials. Furthermore the equipment for Accumulative Roll-Bonding (ARB) is also available at the institute. The fundamental understanding of the structural fragmentation process during Severe Plastic Deformation (SPD), especially at very high strains in single phase materials has been the main research top at the institute. Since HPT is the simplest method to realize very high strains it was the main method applied in the previous projects and it is now the best developed tech-nique at the institute. Actually an upscaling of the HPT equipment is performed, which will permit the SPD of samples larger than 20 mm in diameter and few mm in thickness. In the applied NFN the team of the ESI will be responsible for SPD of required materials for all partners. Besides this basic support, the ESI will focus the attention on two topics – the ductility of SPD materials and the structural evaluation during SPD in composites, which complements the activities of the other NFN partners. The strength of nanostructured materials is usually very high. The advantage of the SPD processed materials is that the ductility is better than those of nanostructured materials processed by other tech-niques. In certain cases the fracture toughness and the ductility is comparable or even better than in coarse grained materials. Therefore, it seems that SPD offers a way to realize a dream of materials scientists to develop high strength materials with good ductility. Both the fracture toughness and the fracture in tension as well as the underlying fracture processes as a function of the SPD microstructure will be analyzed to improve the understanding of the damage process in these materials. In bcc metals and alloys special attention will be devoted to the ductile to brittle transition behavior – the expected goal of SPD is to shift the transition temperature to very low values. A further larger task of the ESI team will be the analyses of the structural evolution during SPD in multiphase metallic materials. The general trend in the structural evolution during SPD of single phase materials is well documented, but for multiphase materials such analyses are very rare. The fragmentation of the microstructure on the grain level as well as on the composite level should be investigated. Moreover, special attention will be focused to the dissolution processes during SPD. The aim of these tasks is the development of a methodology, which permits the prediction of the necessary SPD production steps to generate a desired microstructure.

c/o Physics of Nanostructured Materials

Faculty of Physics

Universität Wien

Boltzmanngasse 5

A-1090 Vienna

T: +43 1 4277 51302

F: +43 1 4277 51326